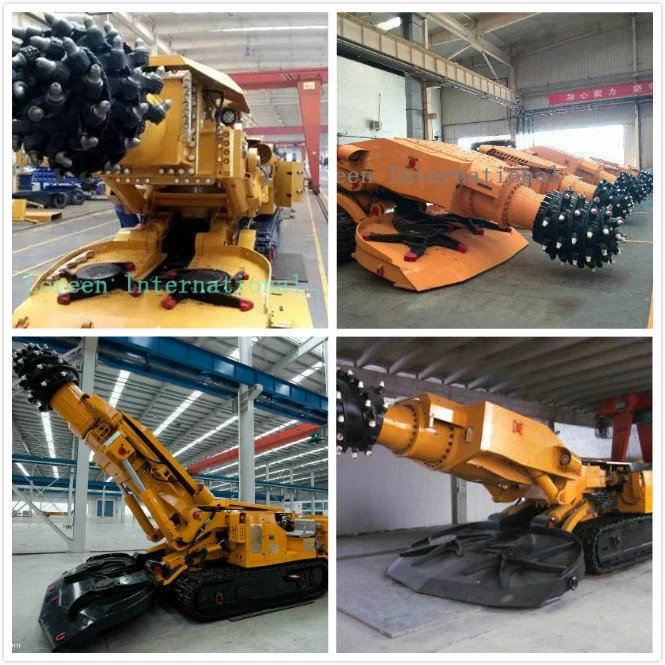

| Product usage The machine is mainly used for coal roadway , semi-coal rock roadway and soft rock roadway and tunnel excavation, which coal rock hardness f≤8 ,to help realize continuous cutting, loading and transportation operations.The maximum ]positioning cutting section can reach 22m2and the gradeability is ±18°.

1.The cutting part has internal and external spray, water leakage detection and protection functions, the cutting motor has thermal protection, the cutting head has a truncated cone shape, and the tooth holder is arranged in a spiral shape.The internal spray seal adopts the world's leading sealing surface compensation technology with independent property rights, which completely solves the problem of unreliability of internal spray in the tunneling machine; 2.The plate working surface adopts double-sided inclination angle, which is convenient for shipping and clearing the bottom. The overall design make machine strength is higher. The charging device is directly driven by the low-speed high-torque motor by the curved three-toothed star wheel; 3.The transport plane adopts middle double-chain, bilateral chain transport structure, which is suitable for the transport of coal, semi-coal rock and rock materials. The base plate is linear and the transport is smooth. The scraper transport is directly driven by two low-speed and high-torque hydraulic motors; 4.The walking part adopts a highly integrated structure of the reducer and the hydraulic motor,small volume and high reliability, and the tensioning device adopts a combined structure of the tightening cylinder and the adjusting pad; 5.The electrical system is controlled by programmable controller and has the functions of new comprehensive protection system module to realize protection, dynamic display of liquid crystal Chinese characters, thermal protection of cutting motor, automatic system fault detection and memory. 6.The pump and operating valve of the hydraulic system adopt the world advanced unit import from German , which has the functions of constant power control, pressure cutting and load sensitive. 7.The rear support device realizes the long span support and improves the machine stability. 8.The walking part adopts a highly integrated structure of the reducer and the hydraulic motor to solve the problem of host self-moving when driving up and down the mountain;The gear ring of reducer box drives the sprocket directly, the volume is small, the torque is big, the tightener device USES the tightener oil cylinder and the adjustment mat composite structure. 9.The strength can be effectively guaranteed by using the military enterprises' matching caterpillar plate, and it can be customized according to different geological conditions. 10.The electrical system is controlled by PLC programming, and the dynamic display of liquid crystal Chinese characters has the function of automatic fault detection and memory, as well as the functions of voltage loss, short-circuit, motor overload, temperature, leakage detection, high and low speed interlocking of cutting motor. 11.The hydraulic system is a crossflow system with good energy saving effect and stable quality. The hydraulic system is equipped with German imported equipment and constant power control. It has pressure cutting and load-sensitive technical functions.The hydraulic valve selects the German import hydraulic control pilot proportion multi-way valve, the quality is reliable, the operation simple saves the effort. 12.Automatic lubrication device is selected for effective lubrication of rotating parts such as pin shaft to guarantee the service life of the equipment.

Our services The company uses the overall resources and platform to provide machine sales, after-sale service, original spare parts supply, large and medium-sized machinery maintenance, technical consultation and on-site construction guidance. 1>The accessories can be supplied by the manufacturer directly, without intermediate fees, and the customer's expenditure is saved to the greatest extent. 2> Besides, our company has a number of technical forces with national certificates. All the technical personnel have many years of field experience in underground and ground installation and debugging, and have a solid theoretical foundation and practical experience. 3>We could provide 7*24H service at the first time for technical support and original accessories supply. 4>Besides provide safe and efficiency equipment. We also provide full service, include Installation and removal of equipment, Equipment overhaul, Driver training for underground Roadheader, Training of maintenance worker on underground site. All in all,the company is responsible for the service concept of "you only need to buy the products with a comfortable and satisfactory product, and the remaining work is to be done" by the service concept, the pre-sale and resale, the heavy quality, the after-sale re-training, the fastest speed, the best technology and the best attitude, to give you a golden service. Why choose us 1.*We could provide 7*24H service at the first time for technical support and original accessories supply. 2.*We also provide full service, include Installation and removal of equipment, Equipment overhaul, Driver training for underground Roadheader, Training of maintenance worker on underground site. 3.*The company has advanced machining equipment, scientific technological process and advanced testing equipment. FAQ 1.What kind terms of payment can be accepted? For terms of payment,L/C,T/T,D/P(can be)could accepted. 2.What certificates are available in Machinery? For the certificate, we have CE, ISO,SGA. 3.What about the delivery time? 60 days after receiving the deposit. 4.What about the warranty time? 12 months after shipment or 2000 working hours, whichever occuts first. 5.What about the Minimum Order Quantity? The MOQ is 1 pcs. Contact If you are interested in our products, you can place an inquiry at the bottom. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||